Page 1302 - Softbound_Edition_19_en

P. 1302

Proportional flow control valve Proportional flow control valve

Proportional flow control valve

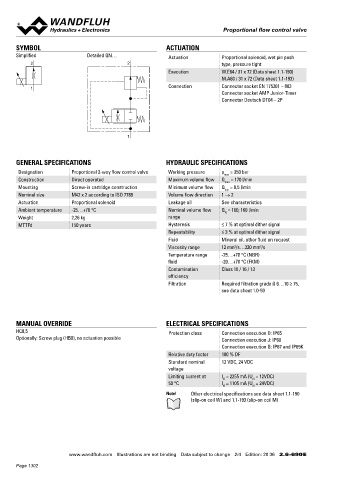

SYMBOL ACTUATION PERFORMANCE SPECIFICATIONS

Simplified Detailed QN… Actuation Proportional solenoid, wet pin push Oil viscosity u = 30 mm /s

2

2 2 type, pressure tight Q = f (I) Volume flow signal characteristics Q = f (p) Volume flow pressure characteristics

Execution W.E64 / 31 x 72 (Data sheet 1.1-190) Q [l/min] Q [l/min]

M.A60 / 31 x 72 (Data sheet 1.1-193) 200 K1126 200 K1127

Connection Connector socket EN 175301 – 803

1 160 Q N = 160 l/min 160 Q N = 160 l/min

Connector socket AMP Junior-Timer 120 120

Connector Deutsch DT04 – 2P Q N = 100 l/min Q N = 100 l/min

80 80

40 40

0 0

0 10 20 30 40 50 60 70 80 90 100 l [%] 0 50 100 150 200 250 300 350 p [bar]

1

Q = f (p) Leakage volume flow characteristics ∆p = f (Q) Pressure drop volume flow characteristic

L

Q [cm /min] p [bar] Q N = 100 l/min Q N = 160 l/min

3

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS 450 K4058 25 K1128

400

350 20

Designation Proportional 2-way flow control valve Working pressure p = 350 bar 300

max 15

Construction Direct operated Maximum volume flow Q = 170 l/min 250

max 200 10

Mounting Screw-in cartridge construction Minimum volume flow Q = 0,5 l/min 150

min 100 5

Nominal size M42 x 2 according to ISO 7789 Volume flow direction 1 → 2 50

Actuation Proportional solenoid Leakage oil See characteristics 0 0 50 100 150 200 250 300 350 p [bar] 0 0 40 80 120 160 200 Q [l/min]

Ambient temperature -25…+70 °C Nominal volume flow Q = 100; 160 l/min

N

Weight 2,26 kg range

MTTFd 150 years Hysteresis ≤ 7 % at optimal dither signal

Repeatability ≤ 3 % at optimal dither signal

Fluid Mineral oil, other fluid on request

2

Viscosity range 12 mm /s…320 mm /s

2

Temperature range -25…+70 °C (NBR) ACCESSORIES SURFACE TREATMENT

fluid -20…+70 °C (FKM) Proportional amplifier Register 1.13 ◆ The cartridge body is gas-nitro-carburised

Contamination Class 18 / 16 / 13 Electric plug B (black) Article no. 219.2002 ◆ The armature tube and the slip-on coil are zinc- / nickel-coated

efficiency Threaded body Data sheet 2.9-205

Filtration Required filtration grade ß 6…10 ≥ 75, Technical explanations Data sheet 1.0-100

see data sheet 1.0-50

Filtration Data sheet 1.0-50 SEALING MATERIAL

NBR or FKM (Viton) as standard, choice in the type code

MANUAL OVERRIDE ELECTRICAL SPECIFICATIONS

HC8,5 Protection class Connection execution D: IP65

Optionally: Screw plug (HB0), no actuation possible Connection execution J: IP66

Connection execution G: IP67 and IP69K INSTALLATION NOTES STANDARDS

Relative duty factor 100 % DF Mounting type Screw-in cartridge M42 x 2 Cartridge cavity ISO 7789

Standard nominal 12 VDC, 24 VDC Mounting position Any, preferably horizontal Solenoids DIN VDE 0580

voltage Tightening torque M = 280 Nm Screw-in cartridge Connection execution D EN 175301 – 803

D

Limiting current at I = 2255 mA (U = 12VDC) M = 5 Nm knurled nut Protection class EN 60 529

D

G

N

50 °C I = 1105 mA (U = 24VDC) M = 9,5 Nm HB0 Contamination efficiency ISO 4406

D

G N

M = 5,5 Nm HC8,5

D

Note! Other electrical specifications see data sheet 1.1-190

(slip-on coil W) and 1.1-193 (slip-on coil M)

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 20 36 2.6-690 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 20 36 2.6-690 E

Page 1302