Page 1399 - Softbound_Edition_19_en

P. 1399

Line mount bodies

Line mount bodies Line mount bodies

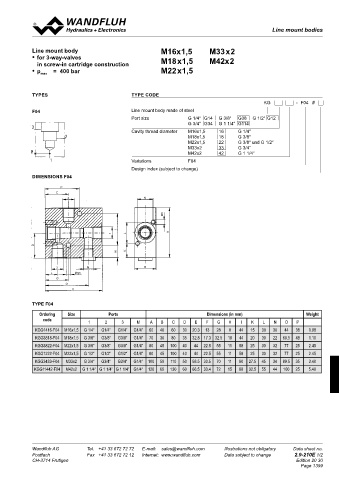

Line mount body M16x1,5 M33x2

GENERAL SPECIFICATIONS SCREW-IN CARTRIDGES INSTALLED

Description Line mount body According to the type the following screw-in cartridges can be installed • for 3-way-valves M18x1,5 M42x2

Mounting 2 location holes in the line mount bodies: in screw-in cartridge construction

2 tapped holes • p = 400 bar M22x1,5

Connection Threated connections Type Data sheet no. max

Mounting position see valve data sheet

Surface protection zinc coated M18x1,5

SDSPM18-BA/AB 1.11-2050 TYPES TYPE CODE

SDYPM18-BA/AB 1.11-2052

HYDRAULC SPECIFICATIONS SDZPM18-BA/AB 1.11-2054 KG - F04 #

Peak pressure p max = 400 bar SVSPM18-BC/CB 1.11-2080 F04 Line mount body made of steel

DN.PM18 2.4-510 Port size G 1/4“ G14 G 3/8“ G38 G 1/2“ G12

DR.PM18 2.4-610

CARTRIDGE CAVITY QA.PM18 2.5-510 G 3/4“ G34 G 1 1/4“ G114

M18x1,5 D.PPM18 2.6-510 Cavity thread diameter M16x1,5 16 G 1/4“

M18x1,5 18 G 3/8“

M22x1,5 M22x1,5 22 G 3/8“ und G 1/2“

SDSPM22-BA/AB 1.11-2060 M33x2 33 G 3/4“

SDYPM22-BA/AB 1.11-2064 M42x2 42 G 1 1/4“

(2)

SVSPM22-BC/CB 1.11-2082 Variations F04

SVYPM22-BC/CB 1.11-2084 Design index (subject to change)

QRSPM22 2.5-530

(1) QZ.PM22 2.5-535 DIMENSIONS F04

DNPPM22 2.6-531

(1) DNPPM22-../ME 2.6-541 P P

QNPPM22 2.6-631 E E

QNPPM22-../ME 2.6-633 2 2 N N

Type Cavity according to: For detailed cavity drawing M33x2

see data sheet: M6 M6

SVSPM33-BC/CB 1.11-2076

M18x1,5 ISO 7789–18–01–0–98 2.13-1002 SVSPM33-BA/AB 1.11-2076

SVYPM33-BC/CB 1.11-2085 I I

M22x1,5 ISO 7789–22–01–0–98 2.13-1008 SVYPM33-BA/AB 1.11-2085 1 1 L L A A

M33x2 ISO 7789–33–01–0–98 2.13-1005 QZ.PM33 2.5-550

DNPPM33 2.6-551 D D

M42x2 ISO 7789–42–01–0–07 2.13-1050 DNPPM33-../ME 2.6-561 H H K K

QNPPM33 2.6-651

QNPPM33-../ME 2.6-659

QSPPM33 2.6-661 3 3 M M B B

F F Ø6,5 Ø6,5

M42x2 G G

SVSPM42-BA/AB 1.11-2091 O O

QNPPM42 2.6-690 C C

TYPE F04

CAUTION!

The performance data refer to the screw-in cartridges only. Ordering Size Ports Dimensions (in mm) Weight

The additional pressure drop in the line mount body must code

be taken into consideration. 1 2 3 M A B C D E F G H I K L N O P

KGG1416-F04 M16x1,5 G 1/4“ G1/4“ G1/4“ G1/4“ 60 40 60 30 20.3 13 28 8 44 15 30 30 44 38 0.98

KGG3818-F04 M18x1,5 G 3/8“ G3/8“ G3/8“ G1/4“ 70 30 80 35 32.8 17.3 32.5 18 44 20 30 22 60.5 48 1.10

Technical explanation see data sheet 1.0-100 KGG3822-F04 M22x1,5 G 3/8“ G3/8“ G3/8“ G1/4“ 80 45 100 40 44 22.5 55 11 58 25 30 32 77 25 2.45

KGG1222-F04 M22x1,5 G 1/2“ G1/2“ G1/2“ G1/4“ 80 45 100 40 44 22.5 55 11 58 25 30 32 77 25 2.45

KGG3433-F04 M33x2 G 3/4“ G3/4“ G3/4“ G1/4“ 100 50 110 50 58.5 30.5 70 11 80 27.5 45 34 89.5 35 3.40

KGG11442-F04 M42x2 G 1 1/4“ G 1 1/4“ G 1 1/4“ G1/4“ 120 60 130 60 66.5 33.4 72 15 88 32.5 55 44 100 25 5.40

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.9-205E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.9-210E 1/2

CH-3714 Frutigen Edition 17 01 CH-3714 Frutigen Edition 20 30

Page 1399