Page 1309 - Softbound_Edition_19_en

P. 1309

Proportional throttle valve

Proportional throttle valves

Proportional throttle valve

Flange and sandwich construction ®

• Direct operated, not pressure compensated NG3-Mini

• Throttle in one flow direction

• Q max = 12 l/min, p max = 250 bar

• Q = 6,3 l/min

N max

DESCRIPTION FUNCTION APPLICATION

Directly operated proportional throttle valve The force controlled proportional solenoid run- Proportional throttle valves are suitable for

in flange or sandwich construction. Screw-in ning in the fluid acts directly on the control spool precise feed control systems. An extremely

cartridge M18x1,5 in accordance with ISO 7789. which opens or closes the triangular shaped sensitive opening and closing response allows

Function optional „normally closed“ or „normally throttling notches in the cartridge body. The a smooth control of movements in stationary or

open“. In sandwich types for A and B line, a throttle opening, and therefore the flow volume, mobile installations, e.g. machine tools, public

by-pass check valve for reversed free flow is changes proportionally to the current absorption vehicles. Mini-3 proportional throttle valves are

in corporated. Two flow ranges are available. of the proportional solenoid. When the solenoid used where hydraulic systems have to be both

The volume flow is adjusted by a proportional is without current, the control spool is held in ligth and compact.

solenoid (VDE standard 0580). the closed position by a spring.

To control the valve proportional amplifiers are

available from Wandfluh (see register 1.13).

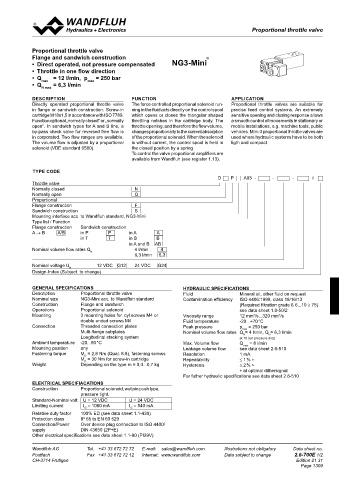

TYPE CODE

D P A03 - - - #

Throttle valve

Normally closed N

Normally open O

Proportional

Flange construction F

Sandwich construction S

Mounting interface acc. to Wandfluh standard, NG3-Mini

Type list / Function

Flange construction Sandwich construction

A → B A/B in P P in A A

in T T in B B

in A and B AB

Nominal volume flow rates Q 4 l/min 4

N

6,3 l/min 6,3

Nominal voltage U 12 VDC G12 24 VDC G24

N

Design-Index (Subject to change)

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Description Proportional throttle valve Fluid Mineral oil, other fluid on request

Nominal size NG3-Mini acc. to Wandfluh standard Contamination efficiency ISO 4406:1999, class 18/16/13

Construction Flange and sandwich (Required filtration grade ß 6...10 ≥ 75)

Operations Proportional solenoid see data sheet 1.0-50/2

Mounting 3 mounting holes for. cyl.screws M4 or Viscosity range 12 mm /s...320 mm /s

2

2

double ended screws M4 Fluid temperature -20...+70 °C

Connection Threaded connection plates Peak pressure p = 250 bar

max

Multi-flange subplates Nominal volume flow rates Q = 4 l/min, Q = 6,3 l/min

N

N

Longitudinal stacking system at 10 bar pressure drop

Ambient temperature -20...50 °C Max. Volume flow Q max = 8 l/min

Mounting position any Leakage volume flow see data sheet 2.6-510

Fastening torque M = 2,8 Nm (Qual. 8.8), fastening screws Resolution 1 mA

D

M = 30 Nm for screw-in cartridge Repeatability ≤ 1 % ∗

D

Weight Depending on the type m = 0,4...0,7 kg Hysteresis ≤ 2 % ∗

∗ at optimal dithersignal

For futher hydraulic specifications see data sheet 2.6-510

ELEKTRICAL SPECIFIACATIONS

Construction Proportional solenoid, wet pin push type,

pressure tight.

Standard-Nominal volt. U = 12 VDC U = 24 VDC

Limiting current I = 1080 mA I = 540 mA

G G

Relative duty factor 100% ED (see data sheet 1.1-430)

Protection class IP 65 to EN 60 529

Connection/Power Over device plug connection to ISO 4400/

supply DIN 43650 (2P+E)

Other electrical specifications see data sheet 1.1-90 (PI29V)

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.6-700E 1/2

CH-3714 Frutigen Edition 21 31

Page 1309