Page 1252 - Softbound_Edition_19_en

P. 1252

Proportional flow control valve Proportional flow control valve

Proportional flow control valve

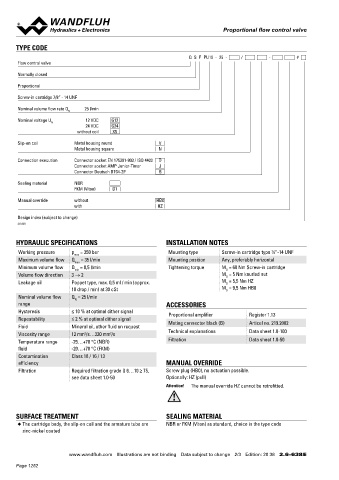

TYPE CODE PERFORMANCE SPECIFICATIONS

2

Q S P PU10 - 25 - / - # Oil viscosity u = 30 mm /s

Flow control valve Q = f (I) Volume flow signal characteristics Q = f (p) Volume flow pressure characteristics

Measured at p = 150 bar I = I

Normally closed G

Q [l/min] Q [l/min]

Proportional K4246 K4247

40 40

Screw-in cartridge 7/8“ - 14 UNF 30 Q N = 25 l/min 30 210 bar Q N = 25 l/min

Nominal volume flow rate Q 25 l/min 20 20

N

Nominal voltage U N 12 VDC G12 10 10

24 VDC G24 0 0

without coil X5 0 10 20 30 40 50 60 70 80 90 100 I [%] 0 50 100 150 200 250 p [bar]

Slip-on coil Metal housing round V

Metal housing square N

DIMENSIONS HYDRAULIC CONNECTION

Connection execution Connector socket EN 175301-803 / ISO 4400 D Cavity drawing according to UNF

Connector socket AMP Junior-Timer J

Connector Deutsch DT04-2P G s30

A 7/8"-14 UNF-2B

Sealing material NBR

*

FKM (Viton) D1 MD=5.5Nm 7/8"-14UNF-2A

76 (3)

Manual override without HB0 (3) (2)

with HZ 37 (1)

(2)

V =

Design index (subject to change)

2.6-638

12 17 10 50 70 60 90 80

MD=5Nm 82.7 61

HYDRAULIC SPECIFICATIONS INSTALLATION NOTES 151.7

Attention! For detailed cavity drawing and cavity tools see data

Working pressure p = 350 bar Mounting type Screw-in cartridge type ⁄8 “-14 UNF

7

max sheet 2.13-1058

Maximum volume flow Q = 35 l/min Mounting position Any, preferably horizontal HB0

max

Minimum volume flow Q = 0,5 l/min Tightening torque M = 60 Nm Screw-in cartridge A

min D MD= 9.5Nm

Volume flow direction 3 → 2 M = 5 Nm knurled nut

D

Leakage oil Poppet type, max. 0,5 ml / min (approx. M = 5,5 Nm HZ 74.8 11

D

10 drop / min) at 30 cSt M = 9,5 Nm HB0 35 PARTS LIST

D

Nominal volume flow Q = 25 l/min Position Article Description

N

range ACCESSORIES N = 15 4 10 206.2... V.E37 / 19 x 50

Hysteresis ≤ 10 % at optimal dither signal Proportional amplifier Register 1.13 260.5... N.S35 / 19 x 50

Repeatability ≤ 2 % at optimal dither signal 10 12 154.2700 Knurled nut

Fluid Mineral oil, other fluid on request Mating connector black (B) Articel no. 219.2002 *After loosening, open further only by hand (without tools). 15 239.2033 Screw plug HB0 (incl. seal)

Viscosity range 12 mm /s…320 mm /s Technical explanations Data sheet 1.0-100 17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

2

2

Temperature range -25…+70 °C (NBR) Filtration Data sheet 1.0-50

fluid -20…+70 °C (FKM) 50 160.2188 O-ring ID 18,77 x 1,78 (NBR)

Contamination Class 18 / 16 / 13 160.8188 O-ring ID 18,77 x 1,78 (FKM)

efficiency MANUAL OVERRIDE STANDARDS 60 160.2140 O-ring ID 14,00 x 1,78 (NBR)

Filtration Required filtration grade ß 6…10 ≥ 75, Screw plug (HB0), no actuation possible. Cartridge cavity Wandfluh standard 160.8140 O-ring ID 14,00 x 1,78 (FKM)

see data sheet 1.0-50 Optionally: HZ (pull) Solenoids DIN VDE 0580 70 160.2120 O-ring ID 12,42 x 1,78 (NBR)

Attention! The manual override HZ cannot be retrofitted. Connection execution D EN 175301 – 803 160.8124 O-ring ID 12,42 x 1,78 (FKM)

Protection class EN 60 529 80 049.8177 Back-up ring PTSM rd 12,4 x 15,3 x 1,4

Contamination efficiency ISO 4406 90 049.8166 Backup ring PTSM rd 10,8 x 13,7 x 1,4

SURFACE TREATMENT SEALING MATERIAL

◆ The cartridge body, the slip-on coil and the armature tube are NBR or FKM (Viton) as standard, choice in the type code

zinc-nickel coated

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 2/3 Edition: 20 38 2.6-638 E www.wandfluh.com Illustrations are not binding Data subject to change 3/3 Edition: 20 38 2.6-638 E

Page 1252