Page 1250 - Softbound_Edition_19_en

P. 1250

Proportional flow control valve Proportional flow control valve

Proportional flow control valve

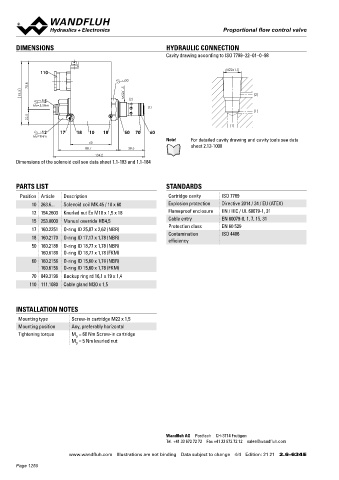

DIMENSIONS HYDRAULIC CONNECTION Proportional 2-way flow control poppet cartridge

Cavity drawing according to ISO 7789–22–01–0–98 ◆ pilot operated 7 ⁄8 “-14 UNF

◆ Q = 35 l/min

max

110 M22x1.5 ◆ Q N max = 25 l/min

◆ p max = 350 bar

s30

70.8

93.3 M22x1.5 (2)

15 (2) DESCRIPTION APPLICATION

MD=5.5Nm (1) Pilot operated, load-compensated proportional flow control poppet These valves are used in hydraulic systems, in which the positio-

(1) valve as screw-in cartridge for UNF cavity. When the solenoid is ning of loads and the simultaneous controlling of the lowering of

22.5 deenergised, the control spool closes practically leakage-free. these loads are demanded. The insensitivity to load changes and

(1) With increasing solenoid current the flow from inlet port (3) to the the very small leakage are a great advantage for this purpose. They

12 17 18 10 18 50 70 60 regulated outlet port (2) increases independently of the load pres- are ideally used in the bypass to the pump. The screw-in cartridge

MD=9Nm For detailed cavity drawing and cavity tools see data

60 Note! sure. For the control, Wandfluh proportional amplifiers are avai- is perfectly suitable for installation in control blocks. For machining

88.7 38.6 sheet 2.13-1008 lable (see register 1.13). the cartridge cavity in steel and aluminum blocks, cavity tools are

134.2 available (hire or purchase). Please refer to the data sheets in

Dimensions of the solenoid coil see data sheet 1.1-183 and 1.1-184 register 2.13.

PARTS LIST STANDARDS

SYMBOL ACTUATION

Position Article Description Cartridge cavity ISO 7789 Simplified Detailed Actuation Proportional solenoid, wet pin pull type,

10 263.6... Solenoid coil MK.45 / 18 x 60 Explosion protection Directive 2014 / 34 / EU (ATEX) 3 3 pressure tight.

12 154.2603 Knurled nut Ex M18 x 1,5 x 18 Flameproof enclosure EN / IEC / UL 60079-1, 31 Execution V.E37 / 19 x 50 (Data sheet 1.1-168)

15 253.8000 Manual override HB4,5 Cable entry EN 60079-0, 1, 7, 15, 31 N.S35 / 19 x 50 (Data sheet 1.1-175)

17 160.2251 O-ring ID 25,07 x 2,62 (NBR) Protection class EN 60 529 2 Connection Connector socket EN 175301 – 803

Contamination ISO 4406

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) efficiency Connector socket AMP Junior-Timer

50 160.2188 O-ring ID 18,77 x 1,78 (NBR) Connector Deutsch DT04 – 2P

160.6188 O-ring ID 18,77 x 1,78 (FKM)

60 160.2156 O-ring ID 15,60 x 1,78 (NBR)

160.6156 O-ring ID 15,60 x 1,78 (FKM)

70 049.3196 Backup ring rd 16,1 x 19 x 1,4

2

110 111.1080 Cable gland M20 x 1,5

INSTALLATION NOTES GENERAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS

Mounting type Screw-in cartridge M22 x 1,5 Designation Proportional 2-way flow control poppet Protection class Connection execution D: IP65

Mounting position Any, preferably horizontal valve Connection execution J: IP66

Tightening torque M = 60 Nm Screw-in cartridge Construction Pilot operated Connection execution G: IP67 and IP69K

D

M = 5 Nm knurled nut Relative duty factor 100 % DF

D Mounting Screw-in cartridge construction

Nominal size 7 ⁄8 “-14 UNF Voltage tolerance ± 10 % with regard to nominal voltage

Actuation Proportional solenoid Standard nominal 12 VDC, 24 VDC

Ambient temperature -25…+70 °C voltage

Weight 0,52 kg Limiting current at I = 1260 mA (U = 12 VDC)

N

G

MTTFd 150 years 50 °C I = 620 mA (U = 24 VDC)

G

N

Note! Other electrical specifications see data sheet 1.1-168

(slip-on coil V) and 1.1-175 (slip-on coil N)

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 21 2.6-634 E www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 20 38 2.6-638 E

Page 1250