Page 1257 - Softbound_Edition_19_en

P. 1257

Proportional flow control valve

Proportional flow control valves Proportional flow control valves

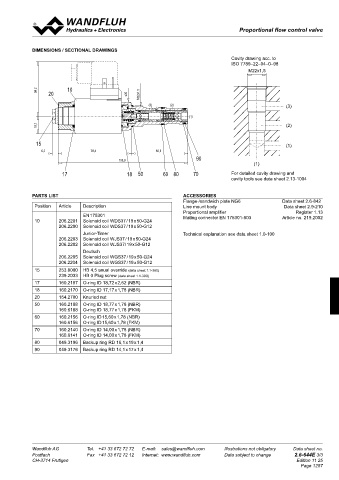

ELECTRICAL SPECIFICATIONS HyDRAuLIC SPECIFICATIONS DImENSIONS / SECTIONAL DRAwINGS

Construction Proportional solenoid, wet pin push type, Fluid Mineral oil, other fluid on request Cavity drawing acc. to

pressure tight Contamination efficiency ISO 4406:1999, class 18/16/13 ISO 7789–22–04–0–98

Standard nominal voltage U = 12 VDC U = 24 VDC (Required filtration grade β 6…10 ≥ 75) M22x1,5

see data sheet 1.0-50/2

Limiting current I = 1360 mA I = 680 mA Viscosity range 12 mm /s…320 mm /s

2

2

G

G

Relative duty factor 100 % ED (see data sheet 1.1- 430) Fluid temperature -20…+70 °C

Protection class Connection version Peak pressure p max = 350 bar 58,2 20 10

= 8 l/min, 15 l/min, 25 l/min

acc. to EN 60 529 D: IP 65 Nominal volume flow rates Q N = 40 l/min (1 → 2) s30 M22x1,5

Q

Max. volume flow

J: IP 66 Min. volume flow max = 0,1 l/min (3) (2)

G: IP 67 and 69K Hysteresis Q min (3)

≤ 7 % ٭

For further electrical specifications see data sheet 1.1-173 (W) ٭ at optimal dither signal (1)

1.1-174 (M)

18,7 (2)

15

CHARACTERISTICS Oil viscosity ν = 30 mm /s (1)

2

6,2 78,4 60,5

Q = f (I) Volume flow adjustment characteristics 1 → 3 (p 3 = 200 bar) Q = f (p) Volume flow pressure characteristics (I = I G )

Q [l/min] Q [l/min] 138,9 90 (1)

30 K0966 Q = 25 l/min 30 K0967 Q = 25 l/min

25 N 25 N 17 18 50 60 80 70 For detailed cavity drawing and

cavity tools see data sheet 2.13-1004

20 20

Q = 16 l/min Q = 16 l/min

N

N

15 15

10 Q = 8 l/min 10 Q = 8 l/min PARTS LIST ACCESSORIES

N

N

5 5 Flange-/sandwich plate NG6 Data sheet 2.6-842

0 0 Position Article Description Line mount body Data sheet 2.9-210

Register 1.13

0 10 20 30 40 50 60 70 80 90 100 I [%] 0 50 100 150 200 250 300 350 p [bar] EN 175301 Proportional amplifier Article no. 219.2002

Mating connector EN 175301-803

10 1 206.2201 Solenoid coil WDS37 / 19 x 50-G24

3

206.2200 Solenoid coil WDS37 / 19 x 50-G12

1

3

2 Junior-Timer Technical explanation see data sheet 1.0-100

Δp = f (Q) Pressure drop-volume flow characteristics 1→ 2 (I = 0 mA) Δp = f (Q) Pressure drop-volume flow characteristics 1 → 3 (I = I G )

206.2203 Solenoid coil WJS37 / 19 x 50-G24

206.2202 Solenoid coil WJS37/ 19 x 50-G12

p [bar] p [bar]

30 K0968 25 K0969 Q = 8 l/min Q = 16 l/min Q = 25 l/min 206.2205 Deutsch 2

N

N

N

Solenoid coil WGS37 / 19 x 50-G24

25 20 206.2204 Solenoid coil WGS37 / 19 x 50-G12

20 15 15 253.8000 HB 4,5 anual override (data sheet 1.1-300)

15 239.2033 HB 0 Plug screw (data sheet 1.1-300)

10 10 17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

5 5 18 160.2170 O-ring ID 17,17 x 1,78 (NBR)

0 0

0 5 10 15 20 25 30 35 40 Q [l/min] 0 5 10 15 20 25 30 Q [l/min] 20 154.2700 Knurled nut

50 160.2188 O-ring ID 18,77 x 1,78 (NBR)

160.6188 O-ring ID 18,77 x 1,78 (FKM)

60 160.2156 O-ring ID 15,60 x 1,78 (NBR)

160.6156 O-ring ID 15,60 x 1,78 (FKM)

70 160.2140 O-ring ID 14,00 x 1,78 (NBR)

160.6141 O-ring ID 14,00 x 1,78 (FKM)

80 049.3196 Backup ring RD 16,1 x 19 x 1,4

90 049.3176 Backup ring RD 14,1 x 17 x 1,4

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.6-644E 2/3 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.6-644E 3/3

CH-3714 Frutigen Edition 11 25 CH-3714 Frutigen Edition 11 25

Page 1257