Page 1347 - Softbound_Edition_19_en

P. 1347

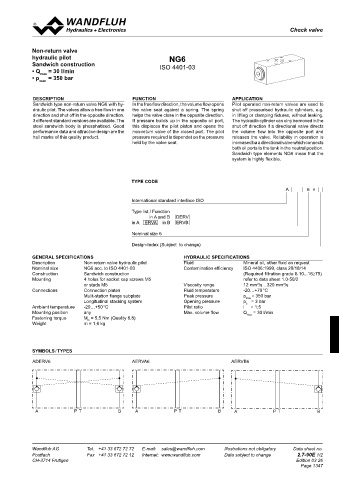

Check valve

Check valves Check valves

CHARACTERISTICS Oil viscosity υ = 30 mm /s Non-return valve

2

∆p = f (Q) Pressure drop charakteristic hydraulic pilot

1 Pressure drop A --> Cyl. or B --> Cyl. Sandwich construction NG6

2 Pressure drop Cyl. --> A or Cyl. --> B ISO 4401-03

with check valve fully open • Q = 30 l/min

BDERV4 BERVA4 BERVB4 • p max = 350 bar

p [bar] max

20 K0082

15

DESCRIPTION FUNCTION APPLICATION

10 Sandwich type non-return valve NG6 with hy- In the free flow direction, the volume flow opens Pilot operated non-return valves are used to

1 draulic pilot. The valves allow a free flow in one the valve seat against a spring. The spring shut off pressurised hydraulic cylinders, e.g.

5 2 direction and shut off in the opposite direction. helps the valve close in the opposite direction. in lifting or clamping fixtures, without leaking.

3 different standard versions are available. The If pressure builds up in the opposite oil port, The hydraulic cylinder can olny be moved in the

A P T 0 B A P T B A P T B steel sandwich body is phosphatised. Good this displaces the pilot piston and opens the shut off direction if a directional valve directs

0 5 10 15 20 Q [l/min] performance data and attractive design are the non-return valve of the closed port. The pilot the volume flow into the opposite port and

hall marks of this quality product. pressure required is dependet on the pressure releases the valve. Reliability in operation is

held by the valve seat. increased ba a directional valve which connects

DIMENSIONS both oil ports to the tank in the neutral position.

Sandwich type elements NG6 mean that the

5,5 20 10 system is highly flexible.

TYPE CODE

A 6 #

30

International standard interface ISO

Type list / Function

in A and B DERV

in A ERVA in B ERVB

6,5 94 6,5

Nominal size 6

Design-Index (Subject to change)

30 40 GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Description

Mineral oil, other fluid on request

Fluid

Non-return valve hydraulic pilot

Nominal size NG6 acc. to ISO 4401-03 Contamination efficiency ISO 4406:1999, class 20/18/14

P Construction Sandwich construction (Required filtration grade ß 10...16≥75)

Mounting 4 holes for socket cap screws M5 refer to data sheet 1.0-50/2

A B or studs M5 Viscosity range 12 mm /s…320 mm /s

2

2

27 14 T To 40 Connections Connection plates Fluid temperature -20…+70 °C

Mulit-station flange subplate Peak pressure p max = 350 bar

Longitudinal stacking system Opening pressure p = 3 bar

ö

Ambient temperature -20…+50 °C Pilot ratio i = 1:5

Mounting position any Max. volume flow Q max = 30 l/min

Fastening torque M = 5,5 Nm (Quality 8.8)

14 Weight m = 1,6 kg

D

28

PARTS LIST

SYMBOLS / TYPES

Position Article Description

ADERV6 AERVA6 AERVB6

10 239.2003 Plug G1/4"

20 049.2212 Bounded seal 21,5x28,7x2,5

30 160.2052 O-Ring ID 5,28x1,78

40 160.2076 O-Ring ID 7,65x1,78

Technical explanation see data sheet 1.0-100

A P T B A P T B A P T B

E-mail: sales@wandfluh.com 20 10

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 5,5 Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.7-70E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.7-90E 1/2

CH-3714 Frutigen Edition 03 26 CH-3714 Frutigen Edition 03 26

Page 1347

42

6,2 110 6,2

30

T

A B

31 21 32,5 45

P

17,8

40,5