Page 1284 - Softbound_Edition_19_en

P. 1284

Proportional flow control valve Proportional flow control valves

Proportional flow control valve

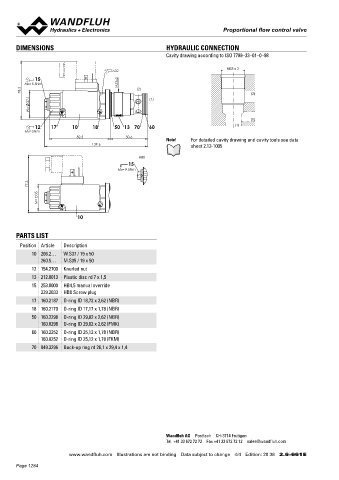

DIMENSIONS HYDRAULIC CONNECTION Proportional 3-way flow control valve

Cavity drawing according to ISO 7789–33–01–0–98 Screw-in cartridge

• Direct operated, pressure compensated m33 x 2

M33 x 2 ISO 7789

s32 • Q max = 100 l/min, p max = 350 bar

15 • Q N max = 63 l/min

MD=5.5Nm M33x2

78.2 (2) (2)

37.1 (1) DESCRIPTION FuNCTION APPLICATION

Direct operated, pressure compensated pro- The 3-way flow control valve serves for maintai- Proportional flow control valves are suitable for

W= portional flow control valve as a screw-in cart- ning the speed of a consumer constant inde- feed control systems, where the consumer flow

ridge with a thread M33 x 2 for cavity acc. to pendent of the load. Superfluous pump output has to be maintained constant with a changing

(1) ISO 7789. Two flow ranges are available. The flow is fed into the return flow system in a cost load. The screw-in cartridge is suitable for in-

12 17 10 18 50 13 70 60 (1) volume flow is adjusted by a Wandfluh propor- saving manner, and as a result, prevents an stallation in control blocs as well as in flange-

MD=5Nm tional solenoid (VDE standard 0580). The cart- overheating of the hydraulic system. The po- and sandwich valves of the size NG10. Cavity

82.5 50.6 ridge body is made of steel. A special surface wer controlled, proportional solenoid running tools are available for machining the cartridge

Note! For detailed cavity drawing and cavity tools see data

139.6 sheet 2.13-1005 treatment guarantees a good protection against in oil acts directly on the throttle spool, which cavities in steel and aluminium (for hire or for

corrosion and wear as well as very good low-

purchase). Please refer to the data sheets in

opens the throttle segments in the cartridge

friction characteristics of the pressure compen- body. Proportional to the current demand of the Reg. 2.13 of our documen-

HB0 sating- and throttle spool. The solenoid coil is proportional solenoid, the throttle aperture tation.

15 zinc- /nickel-coated. changes, and with this the volume flow. In case

MD= 9.5Nm of a current-free solenoid, the throttle spool is

held in closed position by a spring. For driving

77.3 the valve, Wandfluh proportional amplifiers are

available (see Register 1.13).

35

M= TyPE CODE

Q D P PM33 - - / - #

10 Flow control valve

3-way

PARTS LIST Proportional

Position Article Description Screw-in cartridge M33 x 2

10 206.2… W.S37 / 19 x 50 Nominal volume flow rates Q N 32 l/min 32

63 l/min

63

260.5… M.S35 / 19 x 50

12 154.2700 Knurled nut Nominal voltage U N 12 VDC G12

G24

24 VDC

13 212.0013 Plastic disc rd 7 x 1,5 without coil X5

15 253.8000 HB4,5 manual override Slip-on coil Metal housing, round W

10

M33x2

239.2033 HB0 Screw plug 62,2 s36 Metal housing, square M *

(3)

(2)

17 160.2187 O-ring ID 18,72 x 2,62 (NBR) 20 Connection execution Connector socket EN 175301-803 / ISO 4400 D J

Connector socket AMP Junior-Timer

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) 15 Connector Deutsch DT04-2P (1) G

50 160.2298 O-ring ID 29,82 x 2,62 (NBR) Sealing material NBR

160.8298 O-ring ID 29,82 x 2,62 (FMK) 22,5 FKM (Viton) D1

Manual override Armature tube closed (standard)

60 160.2252 O-ring ID 25,12 x 1,78 (NBR) Screwed sealing plug 70 HB0

160.8252 O-ring ID 25,12 x 1,78 (FKM) 2,2 92 Manual emergency actuation 90 HB4.5

79,7

70 049.3296 Back-up ring rd 26,1 x 29,4 x 1,4 Design-Index (Subject to change) 171,7

18

50

17

80

* Only available in conjunction with other nominal voltages 60

and connection versions. (See data sheet 1.1-181)

SymbOLS GENERAL SPECIFICATIONS

simplified detailed Description 3-way proportional flow control valve

Construction Screw-in cartridge for cavity acc. to ISO 7789

Operation Proportional solenoid

Mounting Screw-in thread M33 x 2

Ambient temperature -20…50 °C

1 3 Mounting position any

1 3 Fastening torque M D = 80 Nm for screw-in cartridge

2 M = 7 Nm for knurled nut

D

Weight m = 1,00 kg

Flow direction see symbol

Wandfluh AG Postfach CH-3714 Frutigen 2

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 20 38 2.6-661 E Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.6-666E 1/3

CH-3714 Frutigen Edition 12 23

Page 1284