Page 1334 - Softbound_Edition_19_en

P. 1334

Non-return valve Non-return valves

Non-return valve

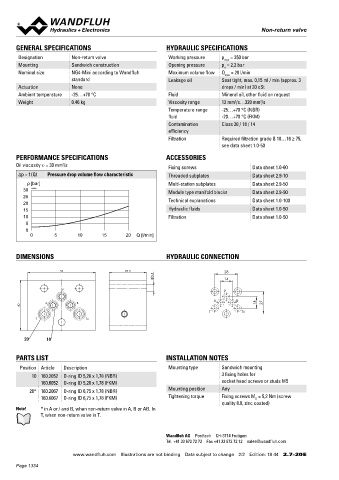

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Non-return valve

Designation Non-return valve Working pressure p = 350 bar Sandwich construction NG6

max

Mounting Sandwich construction Opening pressure p = 2,2 bar • Q = 80 l/min

a max ISO 4401-03

Nominal size NG4-Mini according to Wandfluh Maximum volume flow Q = 20 l/min • p max = 350 bar

max

standard Leakage oil Seat tight, max. 0,15 ml / min (approx. 3

Actuation None drops / min) at 30 cSt

Ambient temperature -25…+70 °C Fluid Mineral oil, other fluid on request

Weight 0.46 kg Viscosity range 12 mm /s…320 mm /s DESCRIPTION FUNCTION APPLICATION

2

2

In the free flow direction, the volume flow opens

Non-return valves allow the volume flow in one

Sandwich type pilot operated non-return valve

Temperature range -25…+70 °C (NBR) NG6 with interface according to ISO 4401-03. the spring loaded valve seat. The spring keeps direction and shuts off in the opposite direction,

fluid -20…+70 °C (FKM) The valves allow a free flow in one direction the valve closed in the opposite direction. The preventing the pressurised fluid from flowing

Contamination Class 20 / 18 / 14 and shut off in the opposite direction. 6 different opening pressure required depends on the back. Non-return valves in the P port prevents

standard versions are available. The steel sand-

backward rotation of the pump. When installed

spring force.

efficiency wich body is phosphatised. Good performance in the T port, the spring controlled opening

Filtration Required filtration grade ß 10…16 ≥ 75, data and attractive design are the hall marks pressure prevents a hydraulic system from

see data sheet 1.0-50 of this quality product. draining to the tank. Sandwich type elements

NG6 make this a highly flexible system.

PERFORMANCE SPECIFICATIONS ACCESSORIES

Oil viscosity u = 30 mm /s Fixing screws Data sheet 1.0-60 TYPE CODE

2

∆p = f (Q) Pressure drop volume flow characteristic Threaded subplates Data sheet 2.9-10 RNNS A06 - #

p [bar] Multi-station subplates Data sheet 2.9-50

30 K0083 Module type manifold blocks Data sheet 2.9-90 Non-return valve, sandwich construction

25 International standard interface ISO, NG6

20 Technical explanations Data sheet 1.0-100

15 Hydraulic fluids Data sheet 1.0-50 Type list / Function

10 Filtration Data sheet 1.0-50 in P P in T T in P and T PT

5 in A A in B B in A and B AB

0 in AV AV in BV BV in AV and BV ABV

0 5 10 15 20 Q [l/min]

Design-Index (Subject to change)

64

GENERAL SPECIFICATIONS 10 40,5 HYDRAULIC SPECIFICATIONS

DIMENSIONS HYDRAULIC CONNECTION Description 40 Non-return valve Fluid Mineral oil, other fluid on request

19

Nominal size NG6 acc. to ISO 4401-03 21,5 Contamination efficiency ISO 4406:1999, class 20/18/14

Construction Sandwich construction (Required filtration grade ß 10…16≥75)

54 29.5 28

5.5 Mounting 4 holes for hexagon socket screw M5 T refer to data sheet 1.0-50/2

14 or studs M5 Viscosity range 12 mm /s…320 mm /s

2

2

Connections Connection plates Fluid temperature -20…+70 °C

P P Multi-station flange subplate Peak pressure p = 350 bar

B

max

Longitudinal stacking system A Opening pressure 21 32,5 45 p = 2 bar

31

5,5

A B Ambient temperature -20…+50 °C Max. volume flow Q ö = 80 l/min

A B 14 27 max

40 Mounting position any

∅

T T0 Fastening torque M = 5,5 Nm (Quality 8.8)

D

T To Weight m = 0,85 kg P

20 10 SYMBOLS / TYPES 17,8

RNNSA06-P RNNSA06-A RNNSA06-AV

PARTS LIST INSTALLATION NOTES

Position Article Description Mounting type Sandwich mounting

10 160.2052 O-ring ID 5,28 x 1,78 (NBR) 3 fixing holes for A PT B RNNSA06-T A PT B RNNSA06-B A PT B RNNSA06-BV

160.6052 O-ring ID 5,28 x 1,78 (FKM) socket head screws or studs M5

20* 160.2067 O-ring ID 6,75 x 1,78 (NBR) Mounting position Any

160.6067 O-ring ID 6,75 x 1,78 (FKM) Tightening torque Fixing screws M = 5,2 Nm (screw

D

quality 8.8, zinc coated) A PT B A PT B A PT B

Note! * in A or / and B, when non-return valve in A, B or AB. In RNNSA06-PT RNNSA06-AB RNNSA06-ABV

T, when non-return valve in T.

A PT B A PT B A PT B

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

www.wandfluh.com Illustrations are not binding Data subject to change 2/2 Edition: 18 44 2.7-20 E Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.7-41E 1/2

CH-3714 Frutigen Edition 21 32

Page 1334